Product Description

Equipment features:1. Ergonomic design, humanized overall space layout;

2. Aisle is designed between the equipment cabin and the tool working cabin to facilitate the staff to operate, maintain and overhaul in different cabin bodies.

3, the cabin body installed air conditioning and lighting facilities, etc., to ensure the operating environment requirements.

4, the workstation is equipped with a global monitoring device to ensure the normal operation of processing operations.

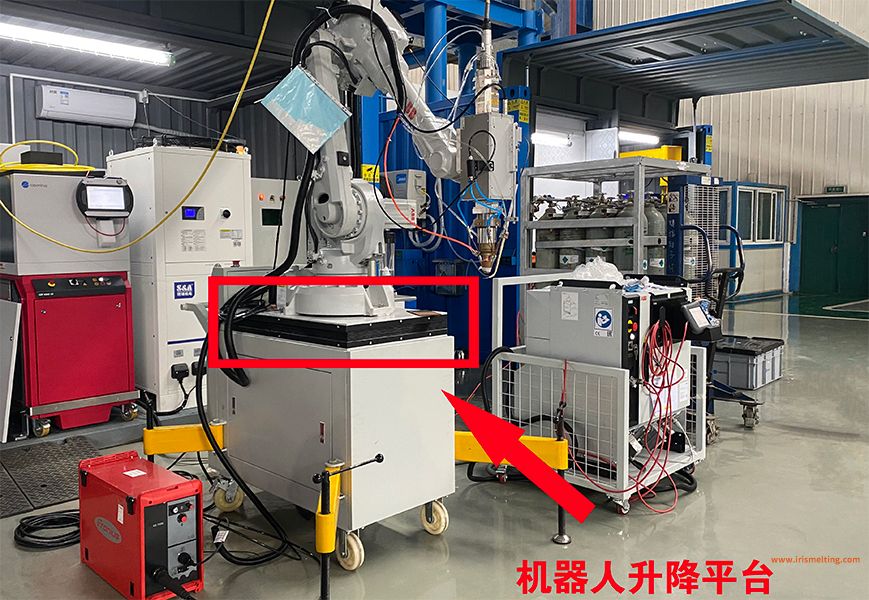

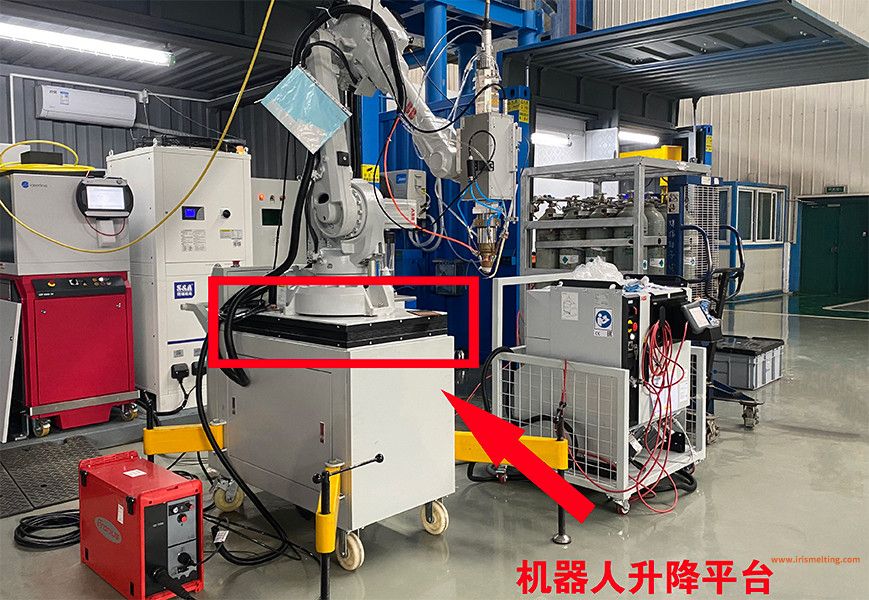

Human mobile lifting platform

Laser cladding robot with mobile chassis can effectively solve the problem of mobile emergency repair of worn workpieces on site.

1, in order to facilitate the robot transport, the robot mobile lifting platform uses a low center of gravity with brake universal wheel structure;

2, for the large workpiece non-rotating, segmented repair operation requirements, the platform is equipped with a solid support, can adjust the support height through the thread movement, overcome the uneven ground and other problems, to ensure the smooth and efficient repair operation of the robot.

Top-opening industrial box-type heat treatment furnace

Top-opening industrial box-type heat treatment furnace continuous steel carburizing process furnace

continuous steel carburizing process furnace Ion nitriding furnace for heat treatment

Ion nitriding furnace for heat treatment trolley furnace Tempering furnace

trolley furnace Tempering furnace high frequency induction heat treatment furnace suppliers

high frequency induction heat treatment furnace suppliers Medium Frequency Scrap Steel Induction Melting Furnace

Medium Frequency Scrap Steel Induction Melting Furnace Medium Frequency Scrap Copper Induction Melting Furnace

Medium Frequency Scrap Copper Induction Melting Furnace HF Induction Melting Gold Furnace

HF Induction Melting Gold Furnace Heat Treatment Electric Furnace Metal Hardening and Tempering Furnace

Heat Treatment Electric Furnace Metal Hardening and Tempering Furnace Mobile laser cladding additive repair workstation

Mobile laser cladding additive repair workstation