Product Description

wire industrial heat treatment annealing furnace with the world's most advanced high-temperature trolley type furnace technology, as an important competitive product of Chinese exports in the international market . Now we are the exclusive exporter for high-temperature trolley type furnace in China. Our plant trolley type furnace has batch production by production line, largest domestic production.

Usage of wire industrial heat treatment annealing furnace:

Main application: Used for heat treatment of general metal parts in the oxidation atmosphere such as normalizing, annealing and quenching.

Application:mainly used in a variety of mechanical parts heat treatment, such as quenching, annealing, normalizing, ageing for roller, steel ball, hammerhead of the crusher, chute liners, high chrome, High Manganese Steel Casting, Gray Iron Castings, nodular iron casting.

Introduction of wire industrial heat treatment annealing furnace:

1.Pallet car furnace shell composed of steel plate and steel welding

2. Lining material is made of super light energy-saving insulation refractory brick masonry, aluminum silicate fiber blanket insulation sandwich, the oven adopts heavy collision brick, car surface heavy high alumina brick molding.

3. A car equipped with chromium manganese nitrogen heat resistant steel furnace bottom or silicon carbide furnace bottom bearing artifacts, in order to prevent the workpiece heated scale through the gaps in the furnace bottom fall into the bottom of the heating element around and cause the damage of the heating element.

4. The rise and fall of pallet car furnace door is through the scroll wheel on the guide rail, scroll up and down and implementation, this not only ensure the oven door closed oven masonry with furnace masonry anastomosis between the seal, And ensure the friction in the process of opening will not damage masonry, the oven door and car movement all is by the motor through the worm gear and worm reducer reducer, chain transmission to provide, and is equipped with electromagnetic brake properly adjusted.

Feature of wire industrial heat treatment annealing furnace:

1.The hot air circulation device makes electric furnace temperature uniformity, the workpiece heated evenly.

2. Electric furnace loading capacity, high productivity, is suitable for various kinds of parts tempering, quenching, preheating.

3. Furnace lining adopts full fiber structure, improve furnace heat preservation performance, save energy, reduce the production cost.

4. Convenient electric furnace with royal material and good operation condition.

5. No pollution, good environmental benefits.

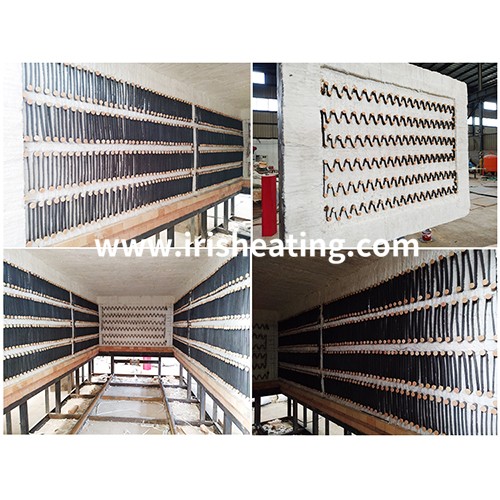

Picture of wire industrial heat treatment annealing furnace:

| Principle |

(1) RT2 series 950 °C, 1100 °C car type resistance furnace

Main application: Used for heat treatment of general metal parts in the oxidation atmosphere such as normalizing, annealing and quenching.

| model | Rated power(KW) | rated temperature(°C) | rated voltage(V) | phase | Chamber size(length×width×high) (mm) | boundary dimension(length×width×high) (mm) |

| RT2-65-9 | 65 | 950 | 380 | 3 | 1100×550×450 | 3060×1582×2480 |

| RT2-65-11 | 65 | 1100 | 380 | 3 | 1100×550×450 | 3060×1582×2480 |

| RT2-105-9 | 105 | 950 | 380 | 3 | 1500×800×600 | 3560×1832×2860 |

| RT2-105-11 | 105 | 1100 | 380 | 3 | 1500×800×600 | 3560×1832×2860 |

| RT2-180-9 | 180 | 950 | 380 | 3 | 2100×1050×750 | 4350×3600×3100 |

| RT2-180-11 | 180 | 1100 | 380 | 3 | 2100×1050×750 | 4350×3600×3100 |

| RT2-320-9 | 320 | 950 | 380 | 3 | 3000×1350×950 | 5500×3100×3550 |

| RT2-320-11 | 320 | 1100 | 380 | 3 | 3000×1350×950 | 5500×3100×3550 |

(2) FXL series fuel oil car type furnace

| model | Rated power(KW) | rated temperature(°C) | rated voltage(V) | phase | Chamber size(length×width×high)(mm) |

| FXL-L1 | 14-22 | 1000 | 380/220 | 3/single | 2000×1600×1800 |

| FXL-L2 | 16-24 | 1000 | 380/220 | 3/single | 3000×2000×2000 |

Top-opening industrial box-type heat treatment furnace

Top-opening industrial box-type heat treatment furnace continuous steel carburizing process furnace

continuous steel carburizing process furnace Ion nitriding furnace for heat treatment

Ion nitriding furnace for heat treatment trolley furnace Tempering furnace

trolley furnace Tempering furnace high frequency induction heat treatment furnace suppliers

high frequency induction heat treatment furnace suppliers Medium Frequency Scrap Steel Induction Melting Furnace

Medium Frequency Scrap Steel Induction Melting Furnace Medium Frequency Scrap Copper Induction Melting Furnace

Medium Frequency Scrap Copper Induction Melting Furnace HF Induction Melting Gold Furnace

HF Induction Melting Gold Furnace Heat Treatment Electric Furnace Metal Hardening and Tempering Furnace

Heat Treatment Electric Furnace Metal Hardening and Tempering Furnace